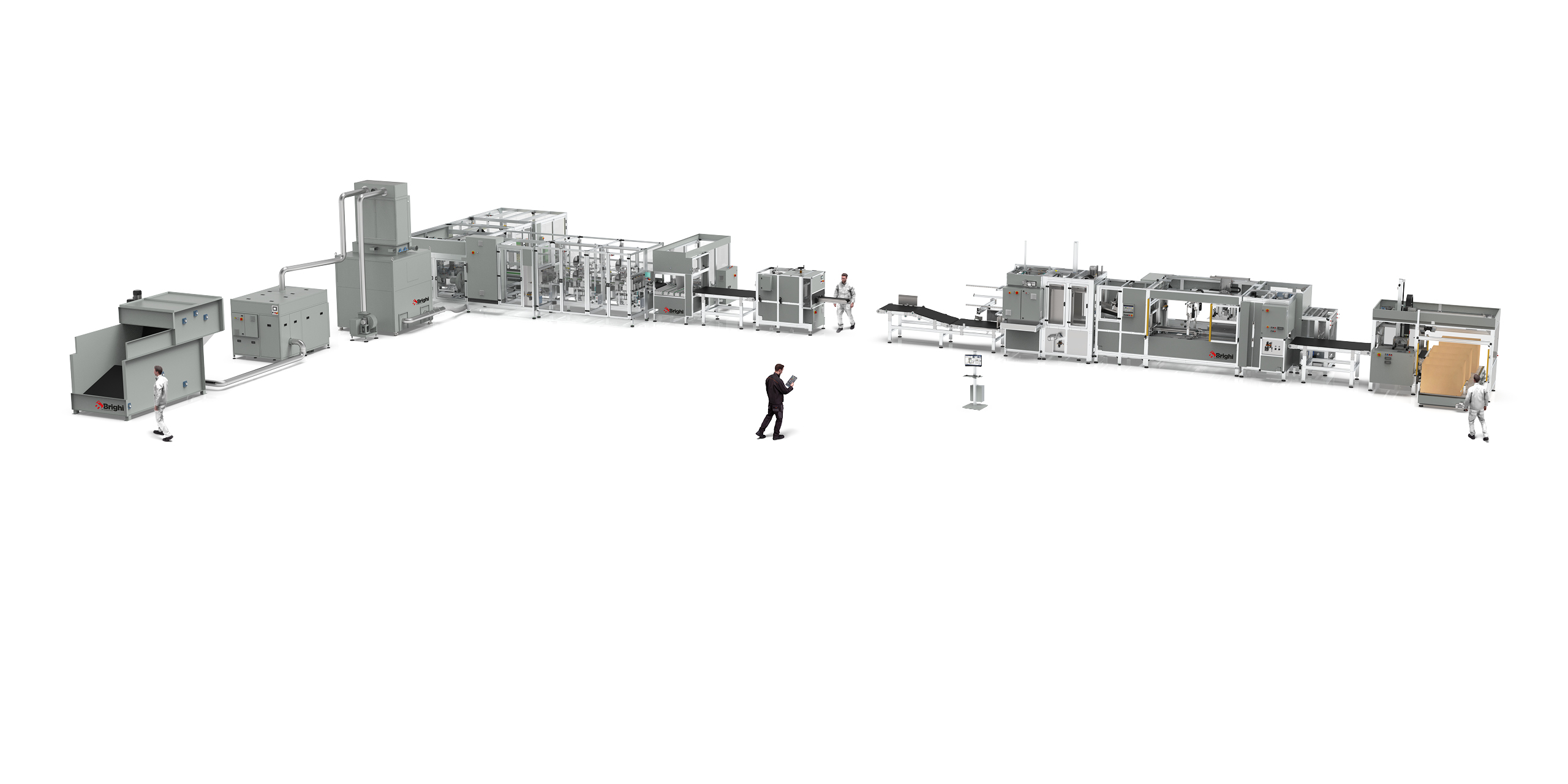

LINE FOR DECORATIVE CUSHIONS AND OUTDOOR CUSHIONS

This line for decorative cushions allows the automatic production of blown decorative cushions filled with loose raw materials. In the configuration we propose a production of decorative blown cushions with an inner cover and an outer cover with zip:

Read more

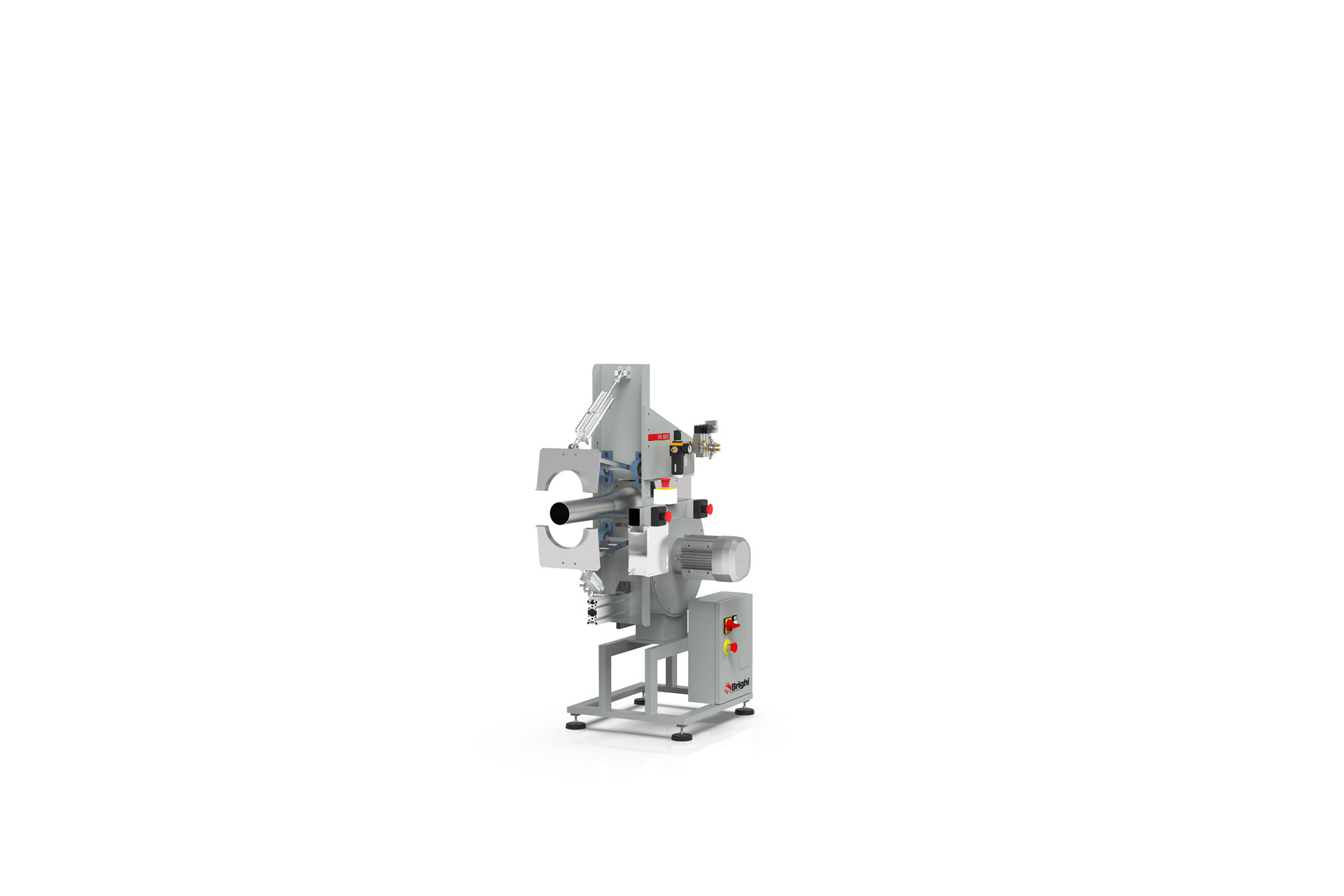

- Fiber bale loader mod. HL-500, which unpacks the material and feeds the following machines. In case of feathers or other loose material it will be necessary to use a specific loader mod. HL-400.

- Fiber opener mod. OF-550, which helps obtaining the maximum opening of the fiber and maximum resilience.

- Fully automatic pre-weighing, filling, sewing and labelling system mod. EBL-500 EASY BLOW: two robots take the covers in parallel from their respective automatic storage, which allows a non-stop supply. The covers are placed on the fillers and held in place during filling with a special clamp system. At the end they move towards the sewing stations.

- Shaker mod. SH-100 to make the product evenly distributed inside the cushion.

- In the case of a second cover with zip, the cushions will be sent to the semi-automatic stuffing machine mod. HF-100, operated by the only operator on the line who will also close the zip.

- Multipack mod. MP-500 which allows the creation of a multipack (more than 2 items in one bag).

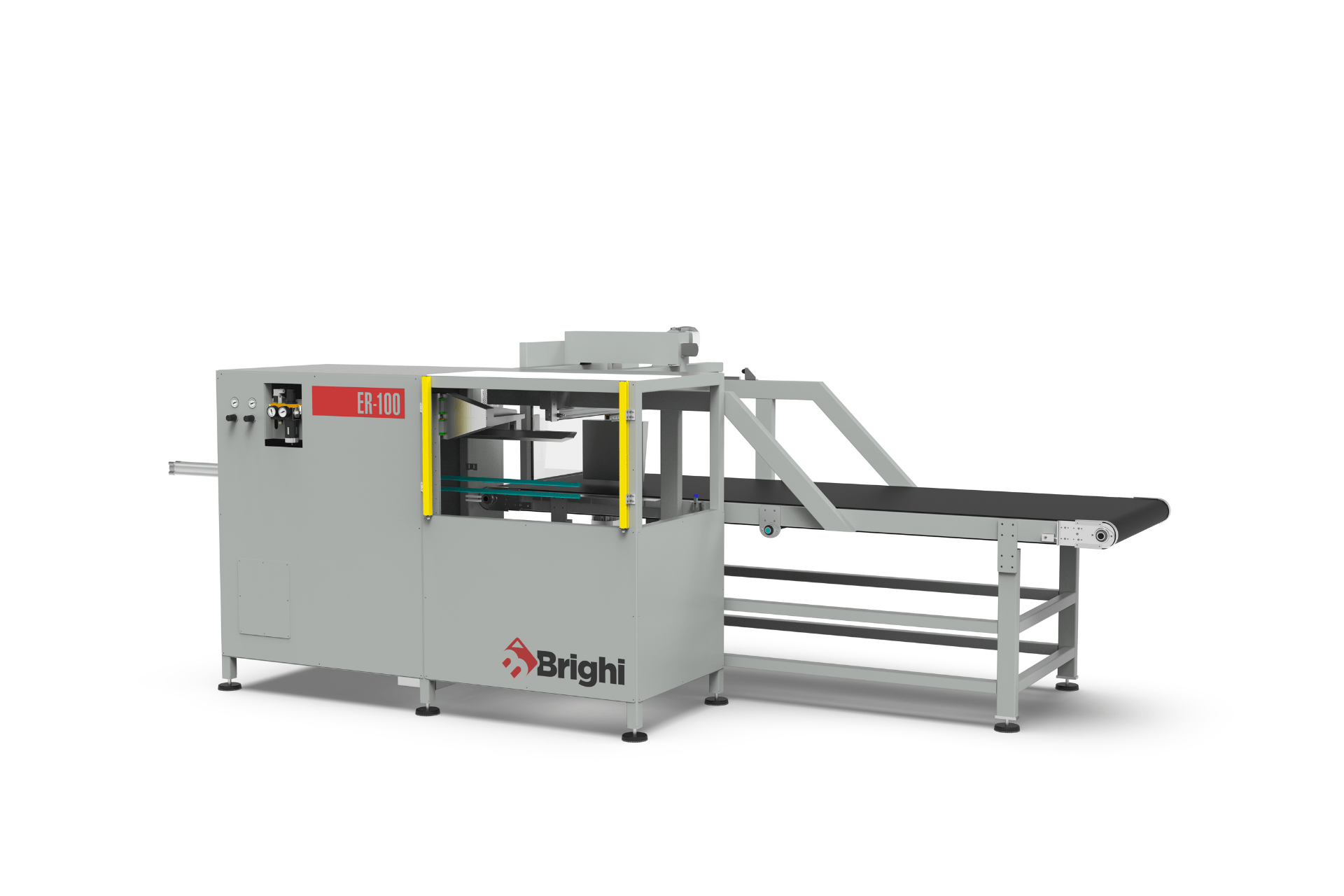

- Automatic bagging machine mod. EB-500 EASY BAG with in-line bag creation module: the stacked cushions are bagged and then compressed and the bag heat-sealed.

- Automatic boxing machine mod. PP-100, which places the bagged products in the sack or carton box, according to the instructions contained in the recipe of the specific product.

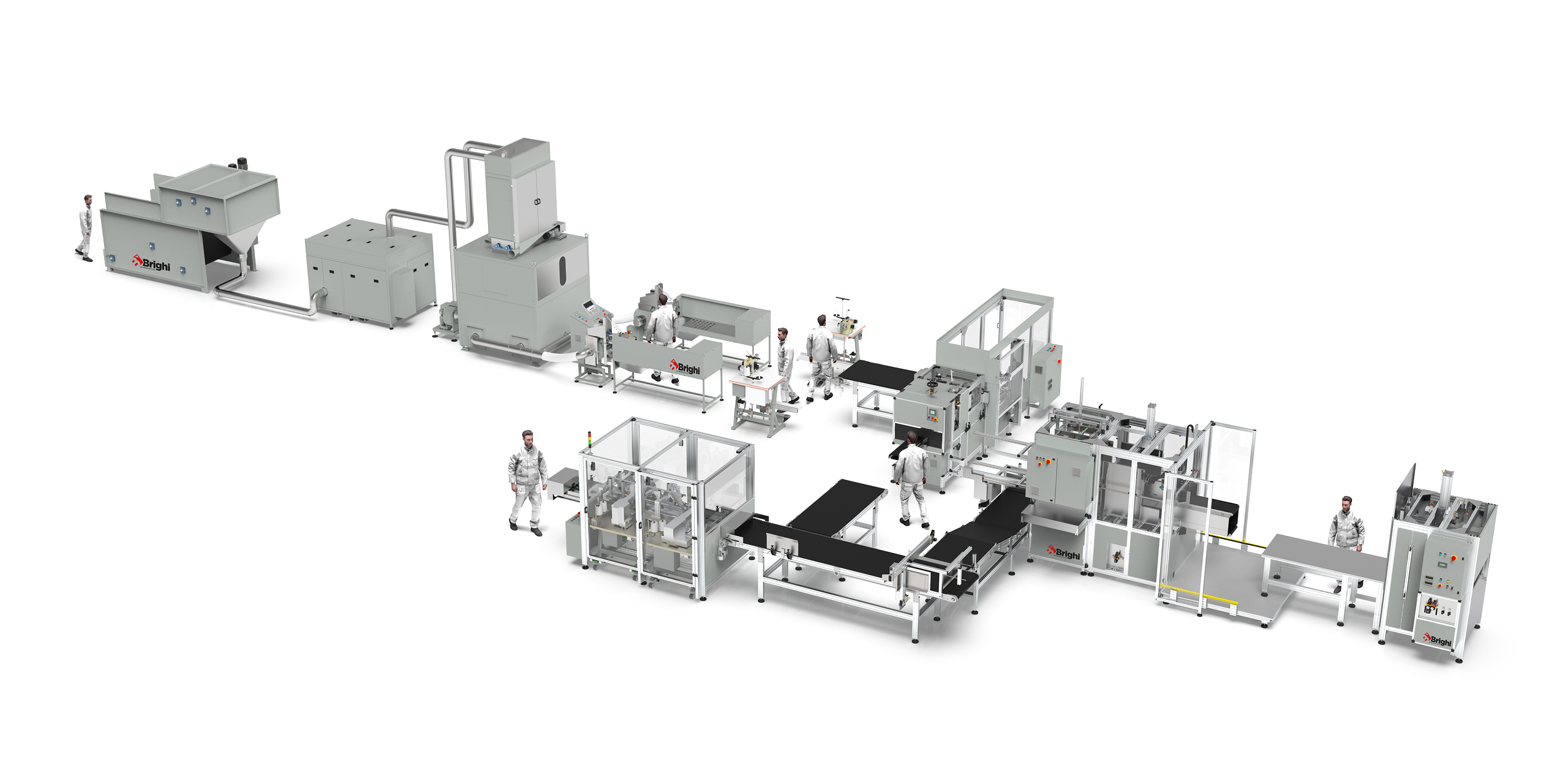

The line for blown outdoor cushions allows the production of products filled with polyester fiber (other loose raw materials also recycled can be planned).

Read more

Here’s a possible configuration:

- Fiber bale loader mod. HL-500, which unpacks the material and feeds the following machine.

- Fiber opener mod. OF-550 to obtain the maximum opening of the product and maximum resilience.

- Pre-weighing and filling system mod. MAC-400, where the operator can manage two filling stations at the same time thanks to the holding fabric clamps.

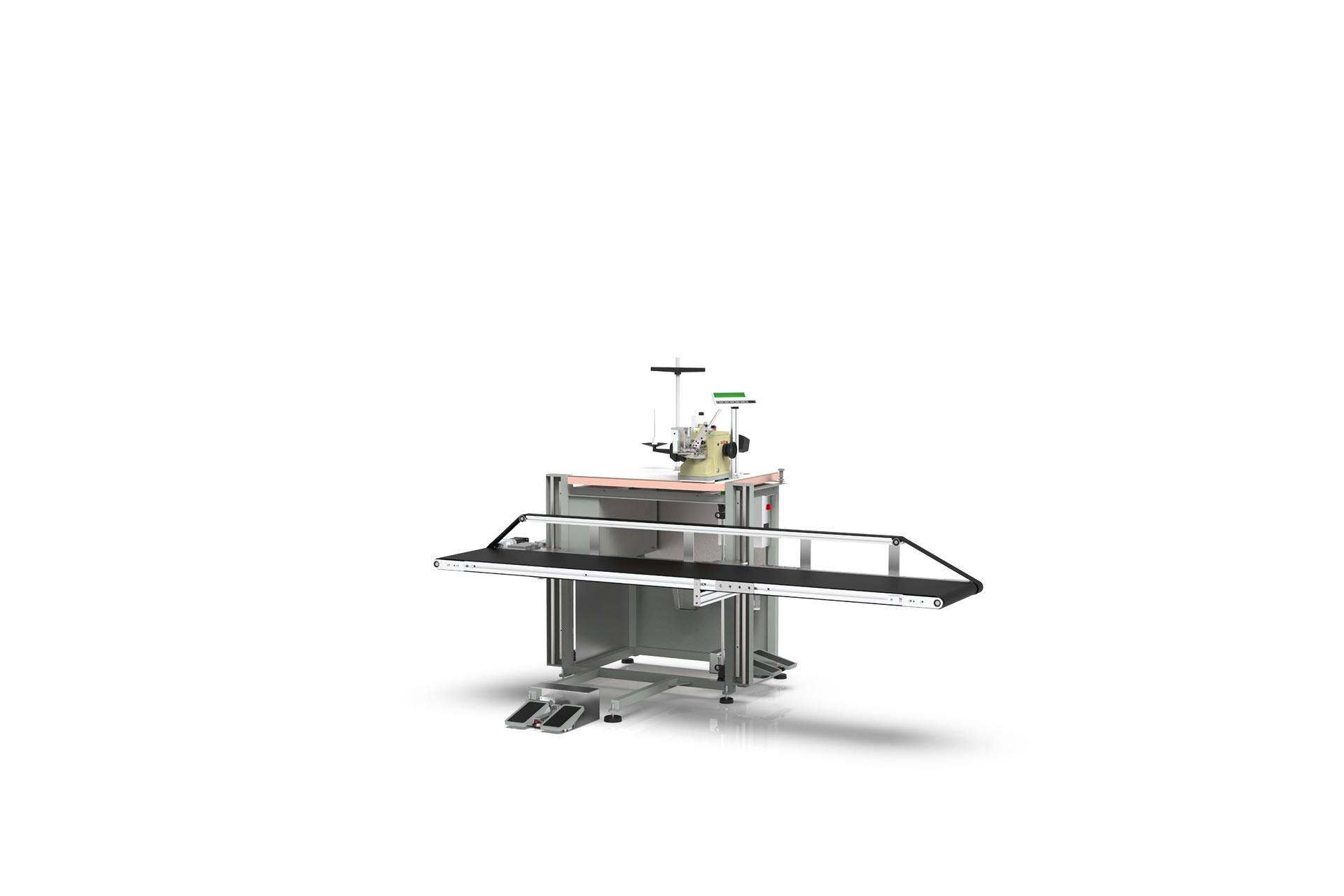

- Linear sewing machines, the number of operators depends on the required production.

- Shaker mod. SH-100 to make the product evenly distributed inside the cushion.

- In the case of a second cover with zip, the cushions will be sent to the semi-automatic stuffing machine mod. HF-100 to be lined by the operator who will also close the zip.

- Multipack mod. MP-400 which allows the creation of a multipack (more than 2 pieces). One operator is needed.

- Sealing machine mod. LF-100 for bag compression and sealing.

- In case of cushions with embroidered stitching, after the filling and sewing process, the cushions are sent to the automatic embroidery machine mod. GA-400-3;

- Main Features

Fully automated process, unique in the market: from raw material to packaged product ready for shipment

Sewing and labeling system with second backup station that intervenes automatically to guarantee non-stop production without machine stops

Performance guaranteed thanks to the electronic management of the machinery that manages all the parameters for production change without mechanical interventions on the plant

Maximum quality standard of the finished product: homogeneous filling, precise stitching and labeling, perfect sealing of the bag, guaranteed vacuum (if required)

Controlled treatment of the raw material: maximum opening of the fiber, significant increase in volume, controlled blends, recycling of waste materials

Accurate pre-weighing system and processing capacity of all raw materials and creation of mixtures with different components

Clean working environment and maximum hygiene in the treatment of raw materials

Quick payback: reduction of labor, transport and storage costs thanks to efficient and automatic flows

Compact and modular line: each module of the line represents a process designed to reduce the use of space and adaptable to any customer environment.

Flexibility and long-lasting investment guarantee with step-by-step implementation of your system as your business requires it

Production data management and monitoring to support strategic and organizational decisions thanks to our Automation Intelligence software