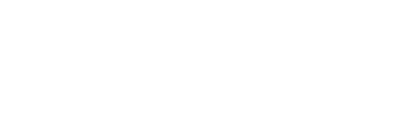

FOAM AND LATEX PILLOW LINE

- HANDLING SYSTEMS

- SEWING

- STUFFING

- PACKAGING

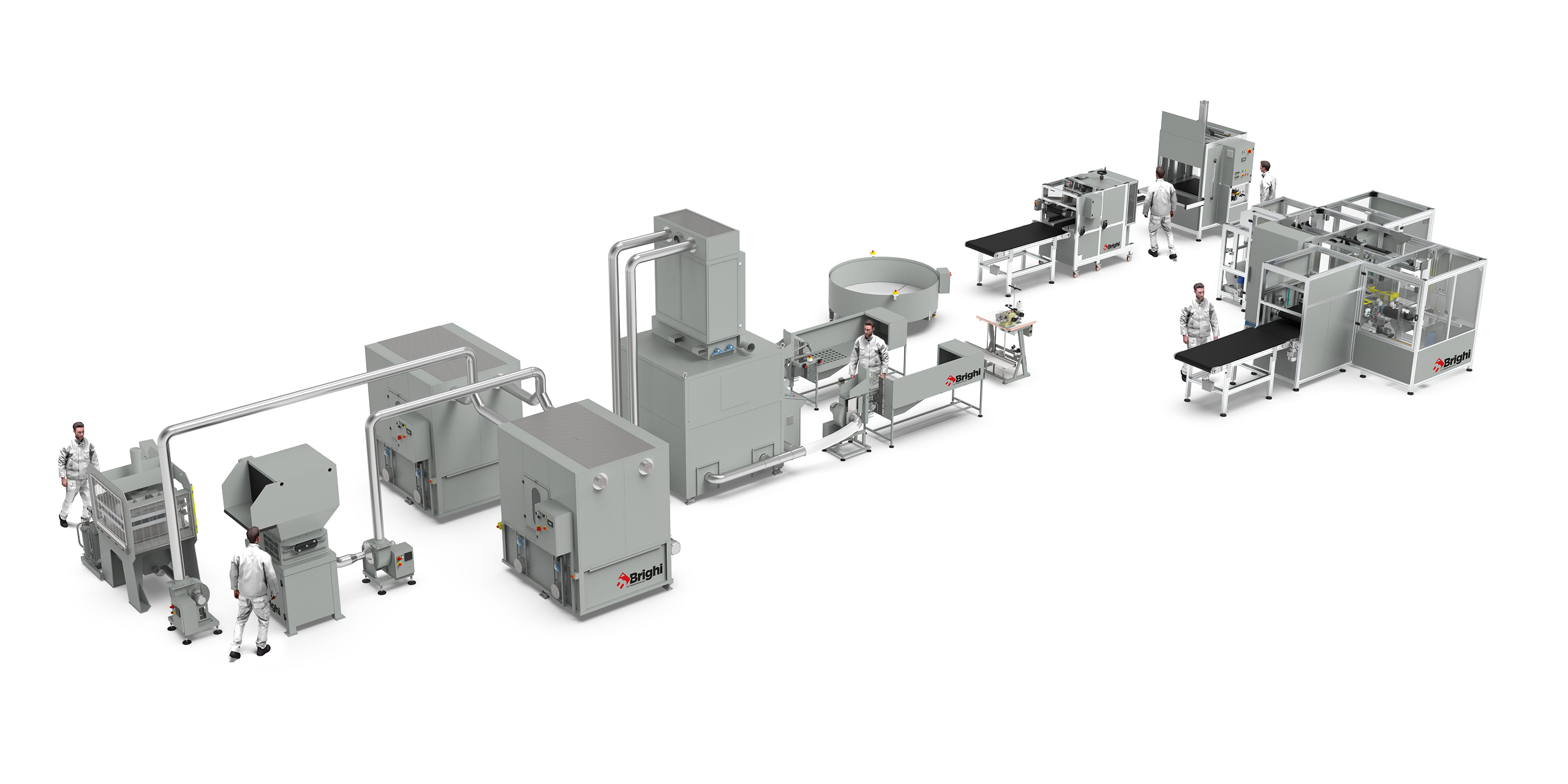

- STUFFING

- RAW MATERIAL PROCESSING

- WASTE RECYCLING

- HANDLING SYSTEMS

- SEWING

- PACKAGING

- STUFFING

- PACKAGING

- Carousel mod. CR-100, the operator loads the cushions coming from the foaming / cutting / drilling area;

- Semi-automatic stuffing machine mod. EP-400 EASY PILLOW with sewing and labelling module. Subsequently the same operator places the cover on the stuffing machine belts and starts the cycle. The “dressed” cushion is then ejected onto a connection belt and automatically sent to the stuffing machine;

- In the case of an additional cover with zip, it will be necessary to insert a manual stuffing machine mod. HF-100 and the use of an operator who inserts the second cover and closes the zip. In the case of cushions that do not require a zip, this process can be completely automatic;

- Twinpack mod. MP-200, which allows you to stack up to two cushions.

- Automatic bagging machine mod. EB-500 EASY BAG, which can simultaneously insert an advertising leaflet, if required.

- Foam punching machine mod. FP-100;

- Mixer mod. MX-500 to create blends;

- Pre-weighing and filling system mod. MAC-400. The operator in charge of filling the cushions can work at the same time on two stations thanks to the fabric clamps;

- Sewing machine mod. G164C, whose special stitch is suitable for closing this type of article. The same operator that works at the previous machine can also close the cushions, optimising the process;

- The manual stuffer mod. HF-100 allows the operator to insert the second lining, close the zip or insert the plastic bag;

- Sealing and possible compression with the LF-100 machine;

- In the case of rolled cushions, the packaging can be completely automatic using the automatic rolling machine mod. ER-500 EASY ROLL.

- Main Features

Simplification of the production process and greater ease and performance in the “dressing” phase of the product

Maximum quality standard of the finished product: homogeneous filling, precise stitching and labeling, perfect sealing of the bag, guaranteed vacuum (if required)

Sewing and labeling system with second back-up station that intervenes automatically to guarantee non-stop production without machine stops

Performance guaranteed thanks to the electronic management of the machinery that manages all the parameters for production change without mechanical interventions on the plant

Accurate pre-weighing system for polyurethane chipboard cushions and ability to process all raw materials and create mixtures with different components

Clean working environment and maximum hygiene in the treatment of raw materials

Quick payback: reduction of labor, transport and storage costs thanks to efficient and automatic flows

Compact and modular line: each module of the line represents a process designed to reduce the use of space and adaptable to any customer environment

Flexibility and long-lasting investment guarantee with step-by-step implementation of your system as your business requires it

Production data management and monitoring to support strategic and organizational decisions thanks to our Automation Intelligence software