ROLLED CARDED FIBER PILLOWS (GARNET)

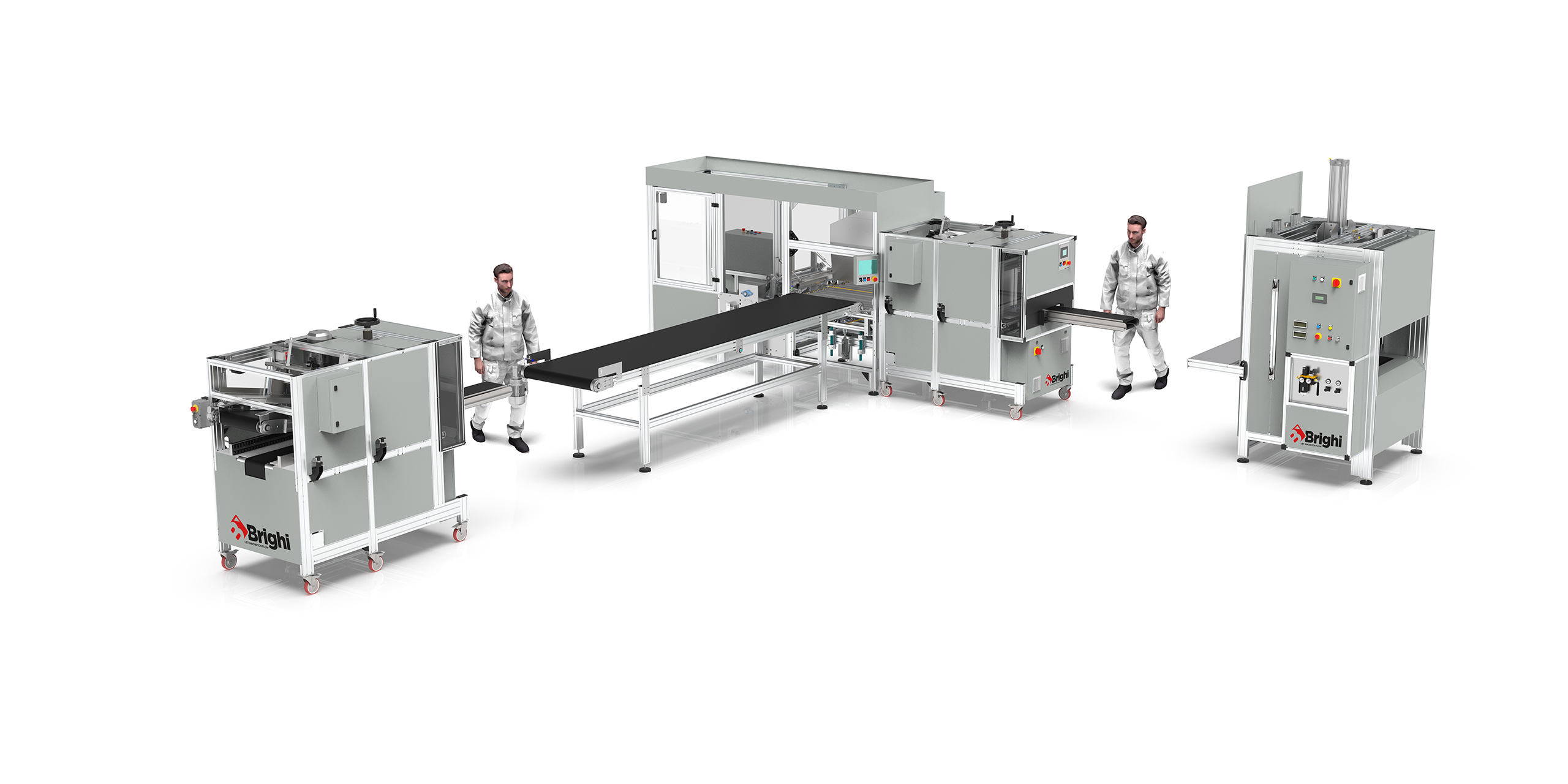

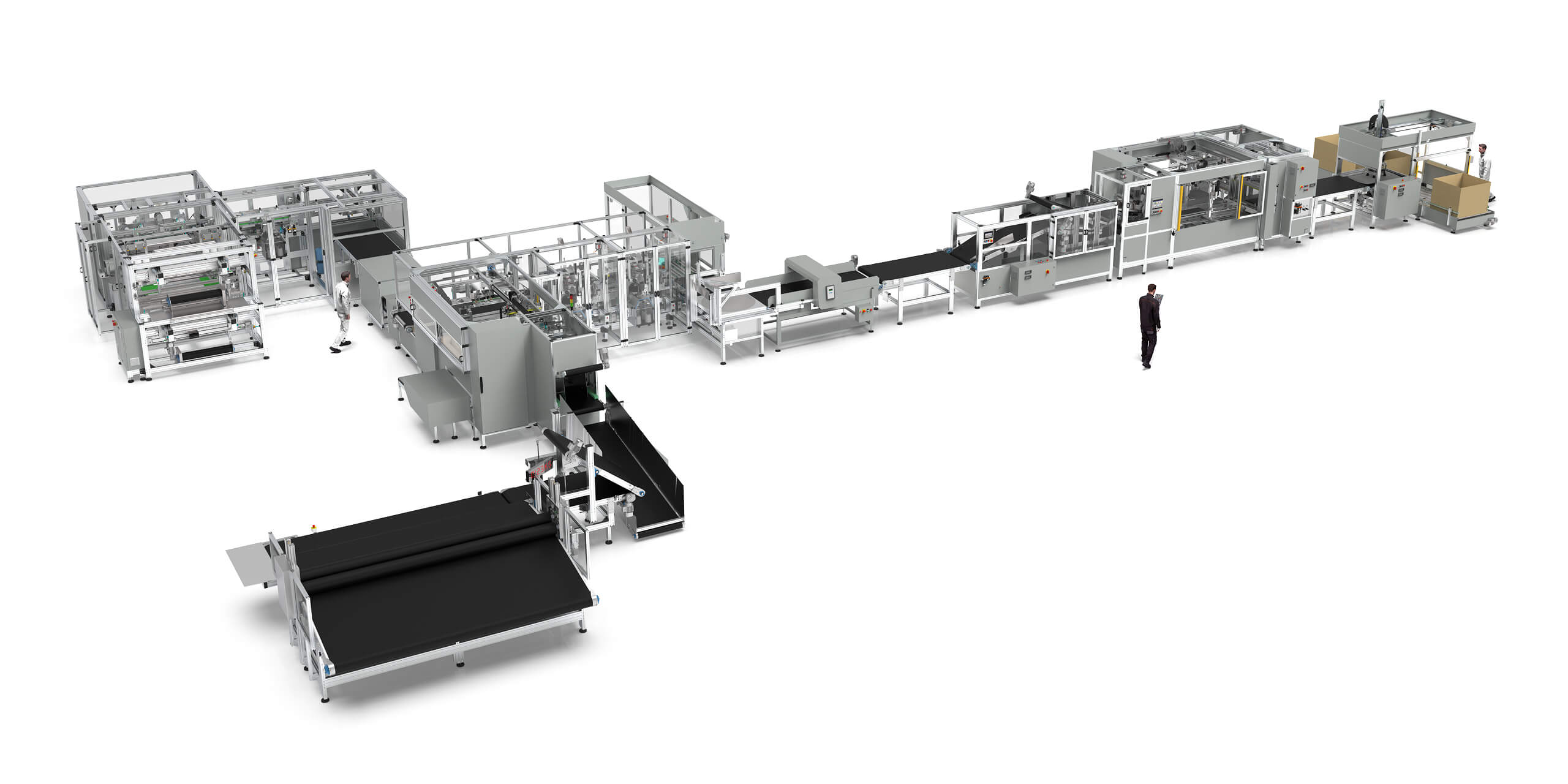

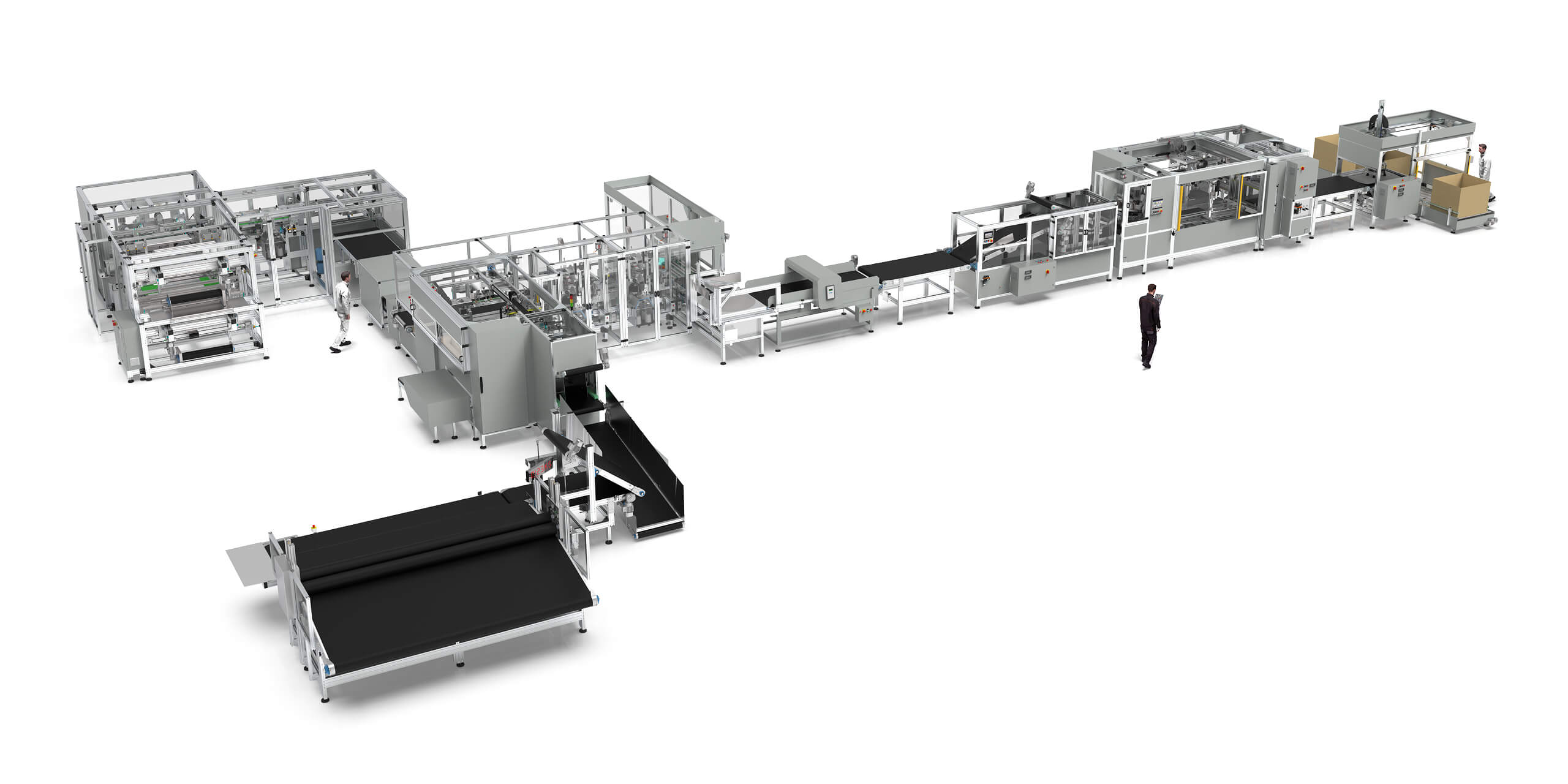

These lines are designed for manufacturing rolled carded fiber pillows, cushions, and other soft goods and they have different levels of automation.

Here’s the configuration for the automatic and semi-automatic solution:

- Cover production machine mod. EC-500 EASY COVER;

- Carded fiber feeding and cutting system mod. CM-100;

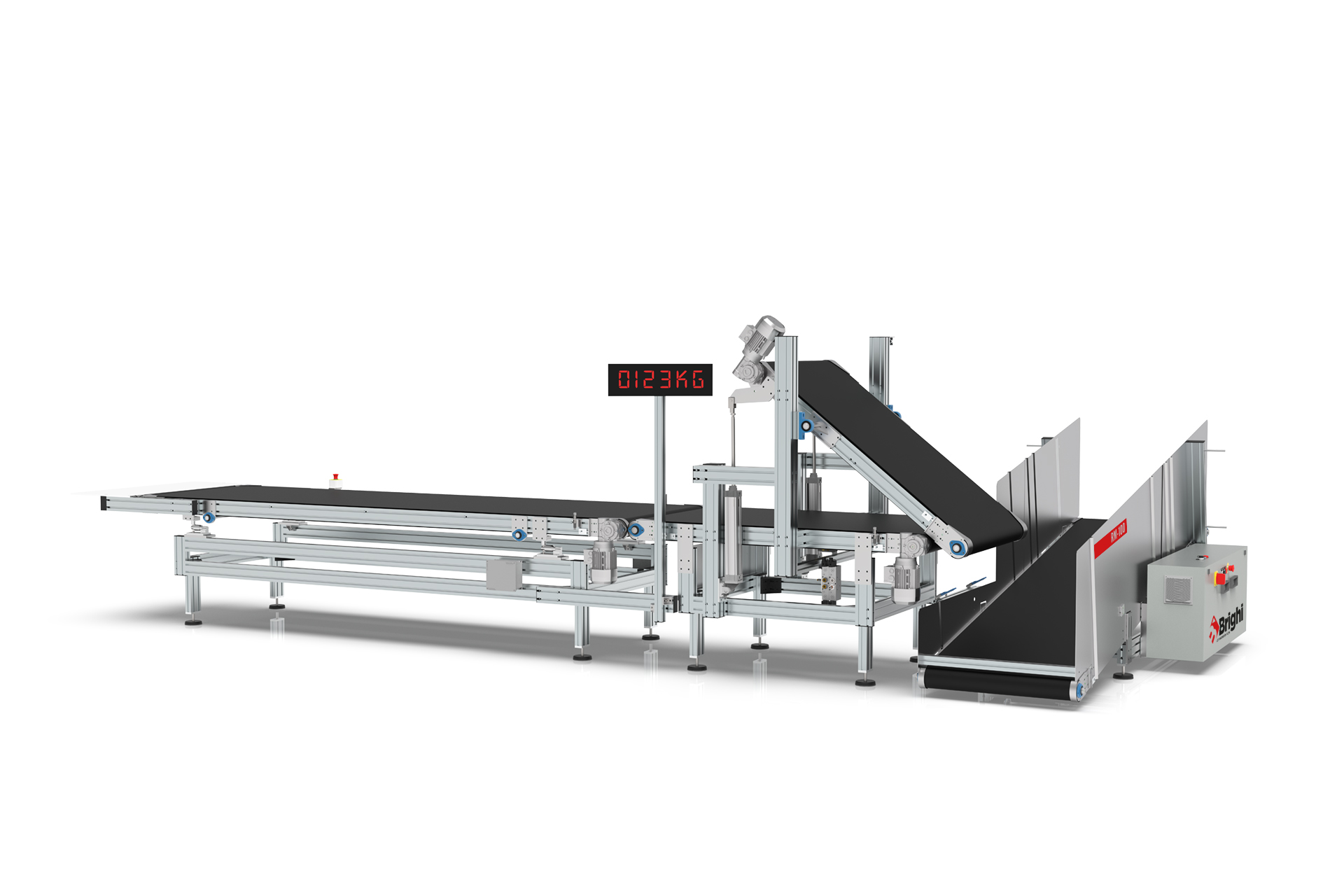

- Carded fiber weighing and rolling machine mod. RM-100;

- Automatic pillow stuffing, sewing and labelling system EP-500 EASY PILLOW with no operator or the semi-automatic version mod. EP-400 EASY PILLOW, which requires one operator.

- Shaker mod. SH-100, to uniform the filling material;

- Twinpack mod. MP-200 that stacks up to two pillows/cushions.

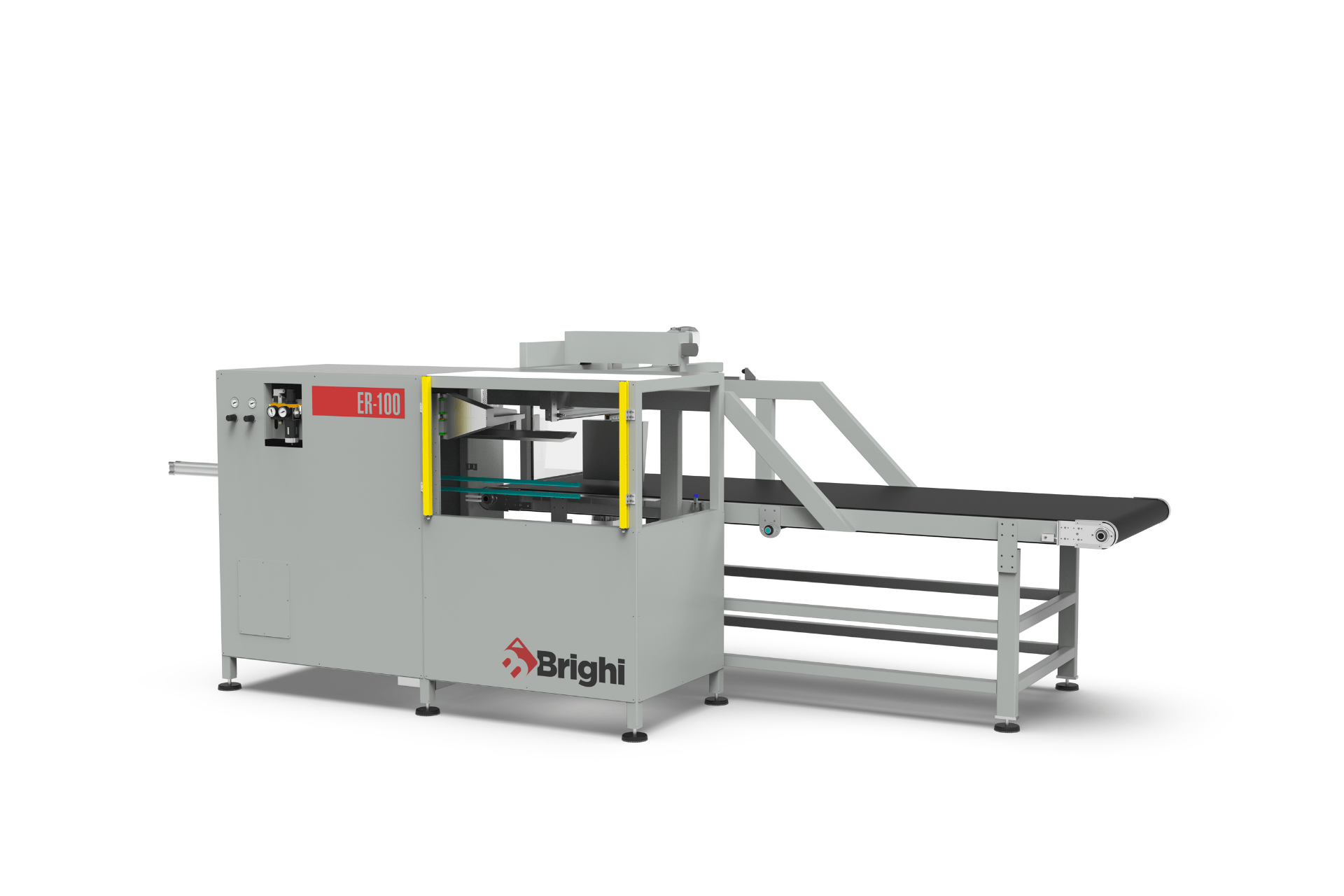

- Automatic bagging machine mod. EB-500 EASY BAG. The cushion/pillow or the two stacked cushions/pillows are packed with the desired compression with no need of an operator. It is also possible to use the semi-automatic version of this machine, mod. EB-400 EASY BAG, which requires one operator.

- Automatic box filling machine mod. PP-100, which picks and places the bagged product in the box, according to the instructions contained in the recipe of the specific product.

To start a manual production, you can use:

- Main Features

Fully automated process, unique in the market: from raw material to packaged product ready for shipment

Sewing and labeling system with second backup station that intervenes automatically to guarantee non-stop production without machine stops

Performance guaranteed thanks to the electronic management of the machinery that manages all the parameters for production change without mechanical interventions on the plant

Maximum quality standard of the finished product: homogeneous filling, precise stitching and labeling, perfect sealing of the bag, guaranteed vacuum (if required)

Clean working environment and maximum hygiene in the treatment of raw materials

Quick payback: reduction of labor, transport and storage costs thanks to efficient and automatic flows

Compact and modular line: each module of the line represents a process designed to reduce the use of space and adaptable to any customer environment.

Flexibility and long-lasting investment guarantee with step-by-step implementation of your system as the business requires it

Production data management and monitoring to support strategic and organizational decisions thanks to our Automation Intelligence software.