QUILTS LINE

The line allows for the accurate folding of quilts in various sizes and their packaging in various ways:

- individually folded in sealed or unsealed bags,

- in a bag with zipper

- in a multiple packing.

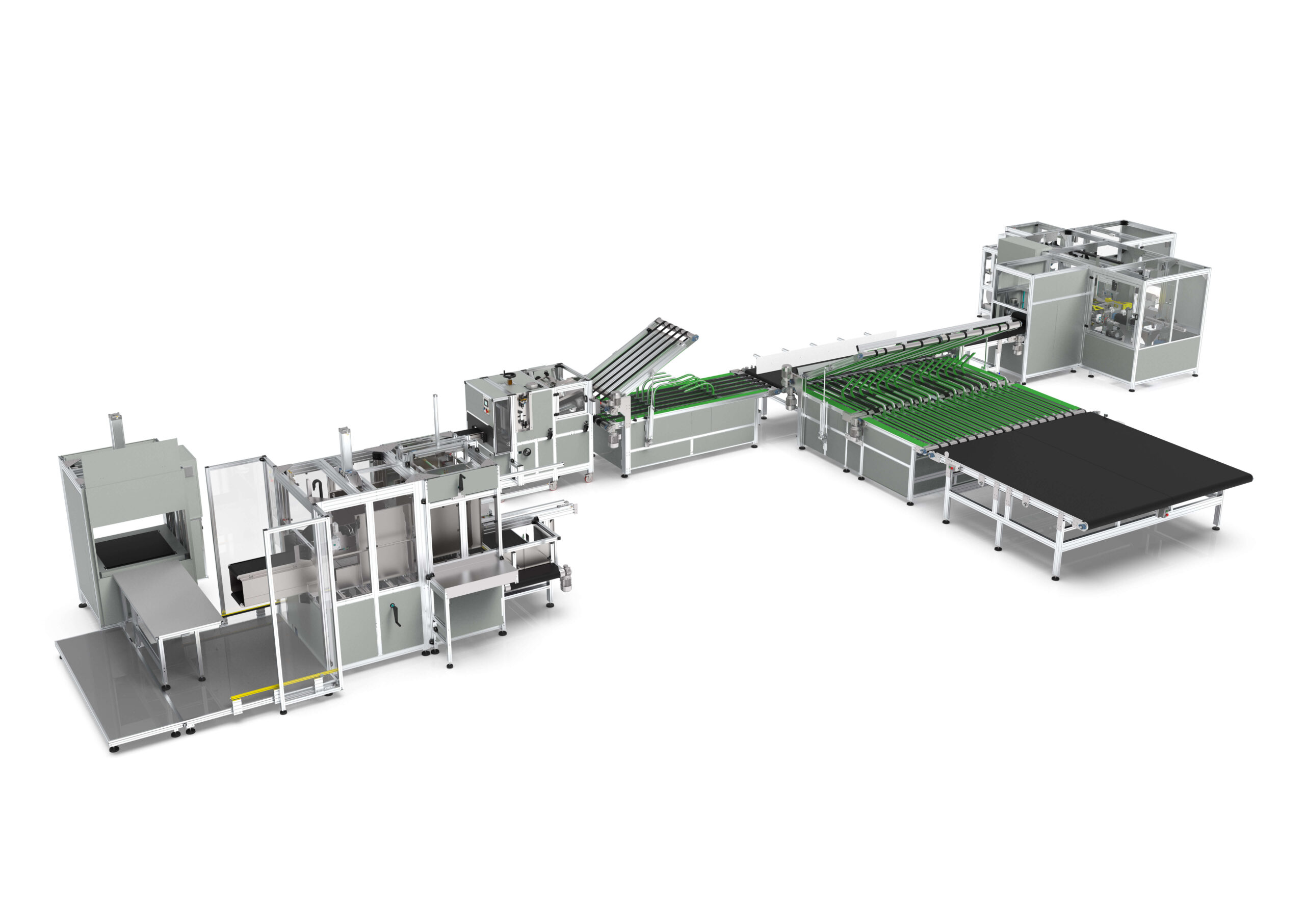

The configuration shows both a semi-automatic version for multiple packaging and rolled packaging.

Here is the configuration shown in the image:

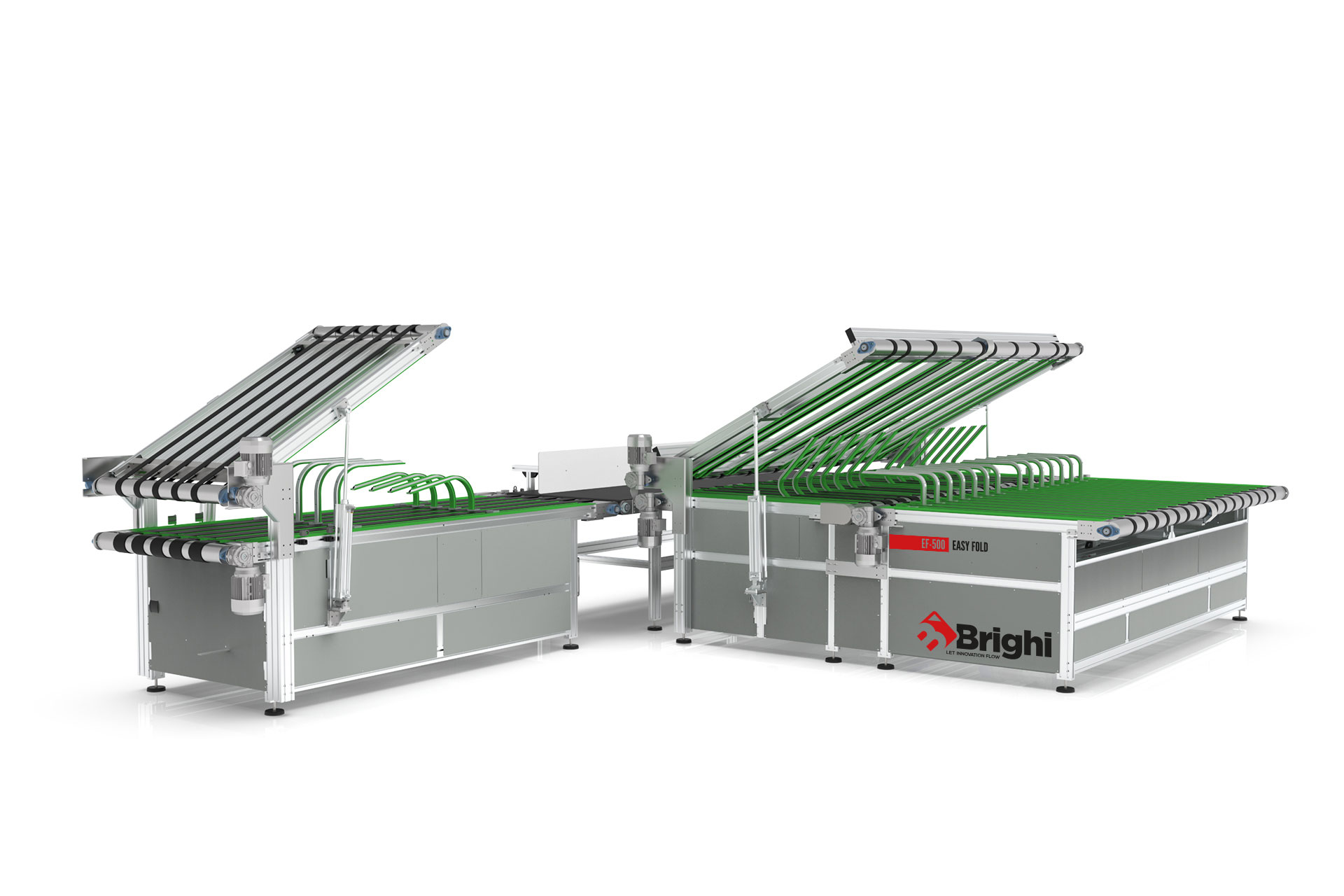

- EF-500 EASY FOLD automatic folding machine: the quilt is placed on the input roller by the operator and then automatically folded by the machine, according to the selected folding pattern (longitudinal and vertical);

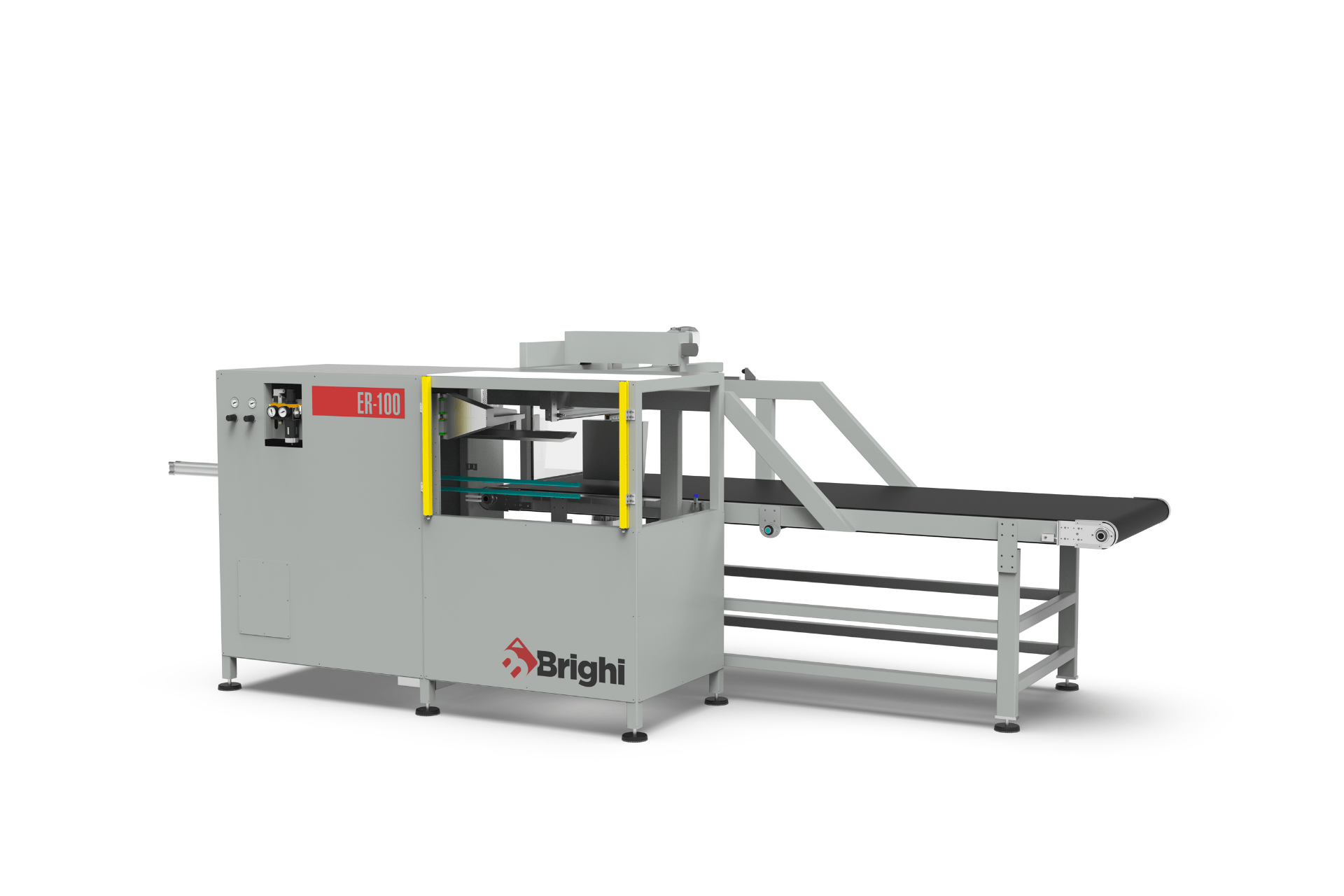

- After the first folding station, the quilt can be transported to the rolling machine ER-500 EASY ROLL;

- If it is not rolled up, the quilt passes through a second folding station and is then bagged in a zip-lock bag using the HF-100 stuffing machine;

- MP-400 multipack packaging station for creating stacks of products to be bagged together;

- Compression and sealing with the machine mod. LF-100.

- Main Features

Specific system for multi-chamber cushions, allowing multiple chambers to be filled simultaneously with different weights

Controlled treatment of raw materials: maximum fiber opening, significant increase in volume, controlled mixtures, recycling of waste materials

Accurate pre-weighing system and processing capacity for all raw materials and creation of mixtures with different components

Highest quality standards for the finished product: uniform filling and special stitching for padded products

Guaranteed performance thanks to electronic machine management that controls all parameters for production changeovers without mechanical intervention on the system.

Clean working environment and maximum hygiene in the handling of raw materials

Fast payback: reduced labor and storage costs thanks to efficient, automated flows

Compact and modular line: each module in the line represents a process designed to reduce space usage and adapt to any customer environment.

Flexibility and guarantee of a long-term investment with step-by-step implementation of your system as your business requires it.

Management and monitoring of production data to support strategic and organizational decisions thanks to our Automation Intelligence software