FROM STATIC TO DYNAMIC MAINTENANCE

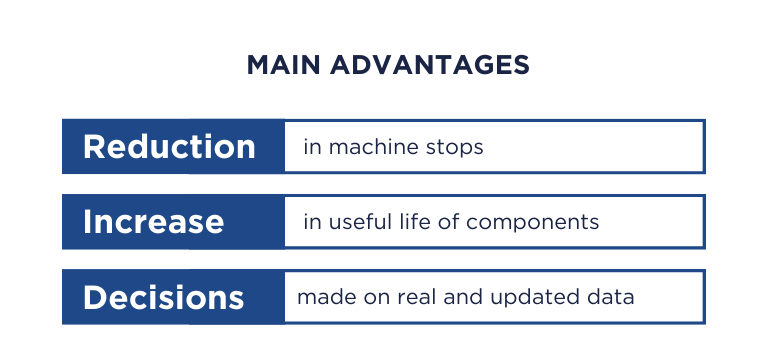

Industrial plants have long relied on static, calendar-based maintenance routines. However, real production environments —characterized by changing operating conditions, and unpredictable downtime—rarely follows a fixed schedule. With IIoT connectivity and Machine Learning, maintenance can now become dynamic: interventions are prioritized and timed by actual asset condition and risk, not by the date on a spreadsheet.

This approach is particularly relevant in pillow manufacturing plants, foam production lines and rebonding facilities, where maintenance inefficiencies directly impact not only throughput but also product quality. Data shows that dynamic maintenance programs have been shown to cut downtime by up to 50% and reduce maintenance costs by 30–40%, while improving throughput and service levels. Let’s look more closely at the main maintenance approaches.

TYPES OF MAINTENANCE

SCHEDULED MAINTENANCE

This is the basic plan set out in your service contract that organizes what work will be done and when (usually calendar-based) and by whom. It creates the routine: inspections, lubrication, replacements, software updates, safety checks.

PREVENTIVE MAINTENANCE

Fixed-interval actions, both time and usage-based, that reduce the risk of surprise failures by performing organized checks and part replacements before they wear out (e.g., replace a bearing every 5,000 hours; calibrate sensors monthly).

PREDICTIVE MAINTENANCE

An evolution of preventive maintenance that uses IoT sensors and data from a digital workflow to read conditions in real time (vibration, temperature, current draw, pressure) and, with analytics, estimates failure probability or Remaining Useful Life (RUL). The system estimates when a fault is likely and alerts the operator before it happens, avoiding wasteful early swaps and last-minute emergencies.

REAL-LIFE APPLICATIONS: DYNAMIC MAINTENANCE ACROSS FOAM, PILLOW AND REBONDING MANUFACTURING

Let’s have a look at real-life examples of how dynamic maintenance is applied to critical equipment across these different manufacturing processes:

- Pillow manufacturing: packaging machines, sealing units, motors

- Foam making: pumps, viscosity control, pressure systems

- Foam rebonding: glue injectors, mixing chambers, dosing systems

Predictive maintenance in pillow manufacturing: reducing downtime in packaging lines

In pillow manufacturing, packaging machines are often the most critical bottleneck, making maintenance strategies essential to ensure continuous production. That’s why one of our customers, a pillow manufacturing start-up, began its digital maintenance journey with an anomaly detection system focused on the packaging machines. A limited but meaningful set of signals, including seal-bar temperature and motor power consumption, was continuously monitored and analyzed.

Deployed in just five months, the system introduced simple, visual reports and standardized alarm logs that immediately reshaped maintenance planning and daily execution. Auto-generated daily summaries highlighted the most frequent recurring stops, allowing planners to schedule short, targeted interventions instead of waiting for longer shutdowns. This shift reduced emergency stops, cut maintenance costs by 48%, and extended component life by avoiding run-to-failure behavior.

Predictive maintenance in foam making to prevent process drift and equipment damage

In foam making processes, maintaining stable pressure and viscosity is crucial to protect pumps and avoid unplanned downtime. For this reason, during foam making production cycles, the machine continuously monitors pressure and viscosity-related fluctuations through in-line sensors and matches them against the flow meter readings. Through the software, the customer can set an acceptable operating range to protect the pump and keep viscosity within specification.

When the process runs close to the defined limit for a certain number of cycles or working hours, the system automatically sends a notification to the maintenance team. This allows the team to plan a targeted intervention in advance, adjusting the feeding temperature to bring viscosity back into range before any damage occurs.

In parallel, the system collects operational data and generates a complete report for the responsible personnel, enabling short, planned micro-interventions that prevent pump failures and reduce unplanned downtime. In this way, maintenance becomes condition-based and predictive, rather than being scheduled only by time.

Predictive maintenance with continuous learning in rebonding lines

In foam rebonding lines, unplanned stops often originate from lack of cleaning of glue injectors inside the mixing chamber. To address this risk, inline condition sensors monitor parameters such as dosing quantity, line performance and remaining time to the next cleaning cycle. These signals are analyzed over time to detect early signs of wear well before functional failure.

When trends cross predefined risk thresholds, the system recommends a controlled stop to inspect and clean the components—avoiding catastrophic failures and extended production losses. Crucially, each intervention is logged in the software along with operating hours, cycles, and inspection findings. This feedback loop allows the system to continuously refine and optimize cleaning and inspection intervals, progressively improving efficiency. Over time, maintenance decisions become not only predictive, but adaptive—driven by real operating data rather than fixed assumptions

WHAT BRIGHI BRINGS TO THE TABLE? DIGITAL DIVISION WITH IN-HOUSE SOFTWARE DEVELOPMENT

We believe the right tools make maintenance smarter, faster, and easier for our customers. That’s why we pair always-on support and high-quality training with a highly effective remote customer service—powered by software we build ourselves for our machines. With this approach, up to 95% of issues are resolved remotely, without waiting for an on-site specialist.

Callisto streamlines scheduling and execution, monitors critical components, and sends proactive alerts as parts approach end-of-life. Formula enables data-driven decisions in foam production. Nebula provides in-depth reporting, real-time machine data, and customizable dashboards for faster decisions. Together, these tools deliver clear visibility, early warnings on recurring alarms, and practical insights on materials and operating methods—so maintenance programs become more efficient, predictable, and resilient.